History

The term "photovoltaic" comes from the Greek φώς (phos) meaning "light", and "voltaic", meaning electrical, from the name of the Italian physicist Volta, after whom the measurement unit volt is named. The term "photo-voltaic" has been in use in English since 1849.[1]

The photovoltaic effect was first recognized in 1839 by French physicist A. E. Becquerel. However, it was not until 1883 that the first solar cell was built, by Charles Fritts, who coated the semiconductor selenium with an extremely thin layer of gold to form the junctions. The device was only around 1% efficient. Russell Ohl patented the modern solar cell in 1946 (U.S. Patent 2,402,662, "Light sensitive device").

Sven Ason Berglund had a prior patent concerning methods of increasing

the capacity of photosensitive cells. The modern age of solar power

technology arrived in 1954 when Bell Laboratories, experimenting with semiconductors, accidentally found that silicon doped with certain impurities was very sensitive to light.

This resulted in the production of the first practical solar cells

with a sunlight energy conversion efficiency of around 6 percent. The

first spacecraft to use solar panels was the US satellite Vanguard 1, launched in March 1958 with solar cells made by Hoffman Electronics. This milestone created interest in producing and launching a geostationary communications satellite,

in which solar energy would provide a viable power supply. This was a

crucial development which stimulated funding from several governments

into research for improved solar cells.

In 1970 the first highly effective GaAs heterostructure solar cells were created by Zhores Alferov and his team in the USSR. [2][3][4]

Metal Organic Chemical Vapor Deposition (MOCVD, or OMCVD) production

equipment was not developed until the early 1980s, limiting the ability

of companies to manufacture the GaAs solar cell. In the United States,

the first 17% efficient air mass zero (AM0)

single-junction GaAs solar cells were manufactured in production

quantities in 1988 by Applied Solar Energy Corporation (ASEC). The

"dual junction" cell was accidentally produced in quantity by ASEC in

1989 as a result of the change from GaAs on GaAs substrates to GaAs on

Germanium (Ge) substrates. The accidental doping of Ge with the GaAs

buffer layer created higher open circuit voltages, demonstrating the

potential of using the Ge substrate as another cell. As GaAs

single-junction cells topped 19% AM0

production efficiency in 1993, ASEC developed the first dual junction

cells for spacecraft use in the United States, with a starting

efficiency of approximately 20%. These cells did not utilize the Ge as

a second cell, but used another GaAs-based cell with different doping.

Eventually GaAs dual junction cells reached production efficiencies of

about 22%. Triple Junction solar cells began with AM0 efficiencies of approximately 24% in 2000, 26% in 2002, 28% in 2005, and in 2007 have evolved to a 30% AM0 production efficiency, currently in qualification. In 2007, two companies in the United States, Emcore Photovoltaics and Spectrolab, produce 95% of the world's Triple Junction solar cells which have a commercial efficiency of 38%. In 2006 Spectrolab's cells achieved 40.7% efficiency in lab testing.[5]

[edit] Three generations of solar cells

Solar Cells are classified into three generations which indicates

the order of which each became prominent. At present there is

concurrent research into all three generations while the first

generation technologies are most highly represented in commercial

production, accounting for 89.6% of 2007 production[6].

[edit] First Generation

First generation cells consist of large-area, high quality and

single junction devices. First Generation technologies involve high

energy and labour inputs which prevent any significant progress in

reducing production costs. Single junction silicon devices are

approaching the theoretical limiting efficiency of 33%[7] and combined with high production costs are unlikely to achieve cost parity with fossil fuel energy generation.

[edit] Second Generation

Second generation materials have been developed to address energy

requirements and production costs of solar cells. Alternative

manufacturing techniques such as vapour deposition and electroplating

are advantageous as they reduce high temperature processing

significantly. It is commonly accepted that as manufacturing techniques

evolve production costs will be dominated by constituent material

requirements,[7] whether this be a silicon substrate, or glass cover. Second generation technologies are expected to gain market share in 2008.[6]

The most successful second generation materials have been cadmium telluride (CdTe), copper indium gallium selenide, amorphous silicon and micromorphous silicon.[6] These materials are applied in a thin film

to a supporting substrate such as glass or ceramics reducing material

mass and therefore costs. These technologies do hold promise of higher

conversion efficiencies, particularly CIGS-CIS, DSC and CdTe

offers significantly cheaper production costs. Among major

manufacturers there is certainly a trend toward second generation

technologies however commercialisation of these technologies has proven

difficult.[8] In 2007 First Solar

produced 200 MW of CdTe solar cells making it the fifth largest

producer of solar cells in 2007 and the first ever to reach the top 10

from production of second generation technologies alone.[8]. Wurth Solar commercialised its CIS technology in 2007 producing 15 MW. Nanosolar commercialised its CIGS technology in 2007 with a production capacity of 430 MW for 2008 in the USA and Germany.[9] In 2007 CdTe production represented 4.7% of total market share, thin film silicon 5.2% and CIGS 0.5%.[8]

[edit] Third Generation

Third generation technologies aim to enhance poor electrical

performance of second generation thin film technologies while

maintaining very low production costs. Current research is targeting

conversion efficiencies of 30-60% while retaining low cost materials

and manufacturing techniques.[7] There are a few approaches to achieving these high efficiencies[10]:

- Multijunction photovoltaic cell.

- Modifying incident spectrum (concentration).

- Use of excess thermal generation to enhance voltages or carrier collection.

[edit] Applications and implementations

Polycrystaline PV cells laminated to backing material in a PV module

Polycrystalline PV cells

Solar cells are often electrically connected and encapsulated as a module. PV modules often have a sheet of glass on the front (sun up) side , allowing light to pass while protecting the semiconductor wafers from the elements (rain, hail, etc.). Solar cells are also usually connected in series in modules, creating an additive voltage.

Connecting cells in parallel will yield a higher current. Modules are

then interconnected, in series or parallel, or both, to create an array with the desired peak DC voltage and current.

The power output of a solar array is measured in watts or kilowatts. In order to calculate the typical energy needs of the application, a measurement in watt-hours, kilowatt-hours or kilowatt-hours per day is often used. A common rule of thumb

is that average power is equal to 20% of peak power, so that each peak

kilowatt of solar array output power corresponds to energy production

of 4.8 kWh per day.

To make practical use of the solar-generated energy, the electricity

is most often fed into the electricity grid using inverters

(grid-connected PV systems); in stand alone systems, batteries are used

to store the energy that is not needed immediately.

[edit] Theory

- See also: Photoelectric effect

[edit] Simple explanation

- Photons in sunlight hit the solar panel and are absorbed by semiconducting materials, such as silicon.

- Electrons (negatively charged) are knocked loose from their atoms, allowing them to flow through the material to produce electricity. The complementary positive charges that are also created (like bubbles) are called holes and flow in the direction opposite of the electrons in a silicon solar panel.

- An array of solar panels converts solar energy into a usable amount of direct current (DC) electricity.

[edit] Photogeneration of charge carriers

When a photon hits a piece of silicon, one of three things can happen:

- the photon can pass straight through the silicon — this (generally) happens for lower energy photons,

- the photon can reflect off the surface,

- the photon can be absorbed by the silicon, if the photon energy is higher than the silicon band gap value. This generates an electron-hole pair and sometimes heat, depending on the band structure.

When a photon is absorbed, its energy is given to an electron in the crystal lattice. Usually this electron is in the valence band,

and is tightly bound in covalent bonds between neighboring atoms, and

hence unable to move far. The energy given to it by the photon

"excites" it into the conduction band,

where it is free to move around within the semiconductor. The covalent

bond that the electron was previously a part of now has one fewer

electron — this is known as a hole. The presence of a missing covalent

bond allows the bonded electrons of neighboring atoms to move into the

"hole," leaving another hole behind, and in this way a hole can move

through the lattice. Thus, it can be said that photons absorbed in the

semiconductor create mobile electron-hole pairs.

A photon need only have greater energy than that of the band gap in

order to excite an electron from the valence band into the conduction

band. However, the solar frequency spectrum approximates a black body spectrum at ~6000 K, and as such, much of the solar radiation reaching the Earth

is composed of photons with energies greater than the band gap of

silicon. These higher energy photons will be absorbed by the solar

cell, but the difference in energy between these photons and the

silicon band gap is converted into heat (via lattice vibrations —

called phonons) rather than into usable electrical energy.

[edit] Charge carrier separation

There are two main modes for charge carrier separation in a solar cell:

- drift of carriers, driven by an electrostatic field established across the device

- diffusion of carriers from zones of high carrier

concentration to zones of low carrier concentration (following a

gradient of electrochemical potential).

In the widely used p-n junction solar cells, the dominant mode of

charge carrier separation is by drift. However, in non-p-n-junction

solar cells (typical of the third generation of solar cell research

such as dye and polymer thin-film solar cells), a general electrostatic

field has been confirmed to be absent, and the dominant mode of

separation is via charge carrier diffusion.[11]

[edit] The p-n junction

The most commonly known solar cell is configured as a large-area p-n junction

made from silicon. As a simplification, one can imagine bringing a

layer of n-type silicon into direct contact with a layer of p-type

silicon. In practice, p-n junctions of silicon solar cells are not made

in this way, but rather, by diffusing an n-type dopant into one side of

a p-type wafer (or vice versa).

If a piece of p-type silicon is placed in intimate contact with a piece of n-type silicon, then a diffusion

of electrons occurs from the region of high electron concentration (the

n-type side of the junction) into the region of low electron

concentration (p-type side of the junction). When the electrons diffuse

across the p-n junction, they recombine with holes on the p-type side.

The diffusion of carriers does not happen indefinitely however, because

of an electric field

which is created by the imbalance of charge immediately on either side

of the junction which this diffusion creates. The electric field

established across the p-n junction creates a diode that promotes current

to flow in only one direction across the junction. Electrons may pass

from the n-type side into the p-type side, and holes may pass from the

p-type side to the n-type side, but not the other way around.[12] This region where electrons have diffused across the junction is called the depletion region because it no longer contains any mobile charge carriers. It is also known as the "space charge region".

[edit] Connection to an external load

Ohmic metal-semiconductor

contacts are made to both the n-type and p-type sides of the solar

cell, and the electrodes connected to an external load. Electrons that

are created on the n-type side, or have been "collected" by the

junction and swept onto the n-type side, may travel through the wire,

power the load, and continue through the wire until they reach the

p-type semiconductor-metal contact. Here, they recombine with a hole

that was either created as an electron-hole pair on the p-type side of

the solar cell, or swept across the junction from the n-type side after

being created there.

[edit] Equivalent circuit of a solar cell

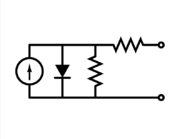

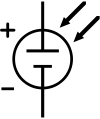

The equivalent circuit of a solar cell

The schematic symbol of a solar cell

To understand the electronic behavior of a solar cell, it is useful to create a model

which is electrically equivalent, and is based on discrete electrical

components whose behavior is well known. An ideal solar cell may be

modelled by a current source in parallel with a diode; in practice no solar cell is ideal, so a shunt resistance and a series resistance component are added to the model.[13]

The resulting equivalent circuit of a solar cell is shown on the left.

Also shown, on the right, is the schematic representation of a solar

cell for use in circuit diagrams.

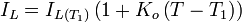

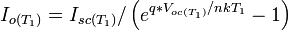

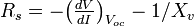

[edit] Circuit Equations defining solar cell

The equations which describe the I-V characteristics of the cell are

|

[edit] Solar cell efficiency factors

[edit] Sun unit

The irradiance of the sun on the outer atmosphere when the sun and

earth are spaced at 1 AU—the mean earth/sun distance of 149,597,870

km—is called the solar constant. Currently accepted values are about

1360 W/m² (the NASA value given in ASTM E 490-73a is 1353 ±21 W/m²).

The World Metrological Organization (WMO) promotes a value of 1367

W/m². The solar constant is the total integrated irradiance over the

entire spectrum (the area under the curve in Fig. 1 plus the 3.7% at

shorter and longer wavelengths. The irradiance falling on the earth's

atmosphere changes over a year by about 6.6% due to the variation in

the earth/sun distance. Solar activity variations cause irradiance

changes of up to 1%. For a solar simulator, it is convenient to

describe the irradiance of the simulator in “suns.” One “sun” is

equivalent to irradiance of one solar constant.[citation needed]

[edit] Energy conversion efficiency

A solar cell's energy conversion efficiency (η,

"eta"), is the percentage of power converted (from absorbed light to

electrical energy) and collected, when a solar cell is connected to an

electrical circuit. This term is calculated using the ratio of the

maximum power point, Pm, divided by the input light irradiance (E, in W/m²) under standard test conditions (STC) and the surface area of the solar cell (Ac in m²).

STC specifies a temperature of 25°C and an irradiance of 1000 W/m²

with an air mass 1.5 (AM1.5) spectrum. These correspond to the

irradiance and spectrum of sunlight incident on a clear day upon a

sun-facing 37°-tilted surface with the sun at an angle of 41.81° above

the horizon.[14][15]

This condition approximately represents solar noon near the spring and

autumn equinoxes in the continental United States with surface of the

cell aimed directly at the sun. Thus, under these conditions a solar

cell of 12% efficiency with a 100 cm2 (0.01 m2) surface area can be expected to produce approximately 1.2 watts of power.

The losses of a solar cell may be broken down into reflectance

losses, thermodynamic efficiency, recombination losses and resistive

electrical loss. The overall efficiency is the product of each of these

individual losses.

Due to the difficulty in measuring these parameters directly, other

parameters are measured instead: Thermodynamic Efficiency, Quantum

Efficiency, VOC ratio, and Fill Factor. Reflectance losses

are a portion of the Quantum Efficiency under "External Quantum

Efficiency". Recombination losses make up a portion of the Quantum

Efficiency, VOC ratio, and Fill Factor. Resistive losses are

predominantly categorized under Fill Factor, but also make up minor

portions of the Quantum Efficiency, VOC ratio.

[edit] Thermodynamic Efficiency Limit

Solar cells operate as quantum energy conversion devices, and are

therefore subject to the "Thermodynamic Efficiency Limit". Photons with

an energy below the band gap of the absorber material cannot generate a

hole-electron pair, and so their energy is not converted to useful

output and only generates heat if absorbed. For photons with an energy

above the band gap energy, only a fraction of the energy above the band

gap can be converted to useful output. When a photon of greater energy

is absorbed, the excess energy above the band gap is converted to

kinetic energy of the carrier combination. The excess kinetic energy is

converted to heat through phonon interactions as the kinetic energy of

the carriers slows to equilibrium velocity.

Solar cells with multiple band gap absorber materials are able to

more efficiently convert the solar spectrum. By using multiple band

gaps, the solar spectrum may be broken down into smaller bins where the

thermodynamic efficiency limit is higher for each bin.[16]

[edit] Quantum efficiency

As described above, when a photon is absorbed by a solar cell it is

converted to an electron-hole pair. This electron-hole pair may then

travel to the surface of the solar cell and contribute to the current

produced by the cell; such a carrier is said to be collected.

Alternatively, the carrier may give up its energy and once again become

bound to an atom within the solar cell without reaching the surface;

this is called recombination, and carriers that recombine do not contribute to the production of electrical current.

Quantum efficiency

refers to the percentage of photons that are converted to electric

current (i.e., collected carriers) when the cell is operated under

short circuit conditions. External quantum efficiency is the fraction of incident photons that are converted to electrical current, while internal quantum efficiency is the fraction of absorbed

photons that are converted to electrical current. Mathematically,

internal quantum efficiency is related to external quantum efficiency

by the reflectance of the solar cell; given a perfect anti-reflection

coating, they are the same.

Quantum efficiency should not be confused with energy conversion efficiency,

as it does not convey information about the power collected from the

solar cell. Furthermore, quantum efficiency is most usefully expressed

as a spectral measurement (that is, as a function of photon

wavelength or energy). Since some wavelengths are absorbed more

effectively than others in most semiconductors, spectral measurements

of quantum efficiency can yield information about which parts of a

particular solar cell design are most in need of improvement.

[edit] VOC ratio

Due to recombination, the open circuit voltage (VOC) of

the cell will be below the band gap voltage of the cell. Since the

energy of the photons must be at or above the band gap to generate a

carrier pair, cell voltage below the band gap voltage represents a

loss. This loss is represented by the ratio of VOC divided by VG

[edit] Maximum-power point

A solar cell may operate over a wide range of voltages (V) and currents (I). By increasing the resistive load on an irradiated cell continuously from zero (a short circuit) to a very high value (an open circuit) one can determine the maximum-power

point, the point that maximizes V×I; that is, the load for which the

cell can deliver maximum electrical power at that level of irradiation.

(The output power is zero in both the short circuit and open circuit

extremes).

A high quality, monocrystalline silicon solar cell, at 25 °C cell

temperature, may produce 0.60 volts open-circuit (Voc). The cell

temperature in full sunlight, even with 25 °C air temperature, will

probably be close to 45 °C, reducing the open-circuit voltage to 0.55

volts per cell. The voltage drops modestly, with this type of cell,

until the short-circuit current is approached (Isc). Maximum power

(with 45 °C cell temperature) is typically produced with 75% to 80% of

the open-circuit voltage (0.43 volts in this case) and 90% of the

short-circuit current. This output can be up to 70% of the Voc x Isc

product. The short-circuit current (Isc) from a cell is nearly

proportional to the illumination, while the open-circuit voltage (Voc)

may drop only 10% with a 80% drop in illumination. Lower-quality cells

have a more rapid drop in voltage with increasing current and could

produce only 1/2 Voc at 1/2 Isc. The usable power output could thus

drop from 70% of the Voc x Isc product to 50% or even as little as 25%.

Vendors who rate their solar cell "power" only as Voc x Isc, without

giving load curves, can be seriously distorting their actual

performance.

The maximum power point of a photovoltaic varies with incident illumination. For systems large enough to justify the extra expense, a maximum power point tracker tracks the instantaneous power by continually measuring the voltage and current (and hence, power transfer), and uses this information to dynamically adjust the load so the maximum power is always transferred, regardless of the variation in lighting.

[edit] Fill factor

Another defining term in the overall behavior of a solar cell is the fill factor (FF). This is the ratio of the maximum power point divided by the open circuit voltage (Voc) and the short circuit current (Isc):

[edit] Comparison of energy conversion efficiencies

At this point, discussion of the different ways to calculate

efficiency for space cells and terrestrial cells is necessary to

alleviate confusion. In space, where there is no atmosphere, the

spectrum of the sun is relatively unfiltered. However on earth, with

air filtering the incoming light, the solar spectrum changes. To

account for the spectral differences, a system was devised to calculate

this filtering effect. Simply, the filtering effect ranges from Air Mass

0 (AM0) in space, to approximately Air Mass 1.5 on earth. Multiplying

the spectral differences by the quantum efficiency of the solar cell in

question will yield the efficiency of the device. For example, a

Silicon solar cell in space might have an efficiency of 14% at AM0, but

have an efficiency of 16% on earth at AM 1.5. Terrestrial efficiencies

typically are greater than space efficiencies.

Solar cell efficiencies vary from 6% for amorphous silicon-based

solar cells to 40.7% with multiple-junction research lab cells and

42.8% with multiple dies assembled into a hybrid package.[17] Solar cell energy conversion efficiencies for commercially available multicrystalline Si solar cells are around 14-19%[18].

The highest efficiency cells have not always been the most economical —

for example a 30% efficient multijunction cell based on exotic

materials such as gallium arsenide or indium selenide and produced in

low volume might well cost one hundred times as much as an 8% efficient

amorphous silicon cell in mass production, while only delivering about

four times the electrical power.

However, there is a way to "boost" solar power. By increasing the

light intensity, typically photogenerated carriers are increased,

resulting in increased efficiency by up to 15%. These so-called

"concentrator systems" have only begun to become cost-competitive as a

result of the development of high efficiency GaAs cells. The increase

in intensity is typically accomplished by using concentrating optics. A

typical concentrator system may use a light intensity 6-400 times the

sun, and increase the efficiency of a one sun GaAs cell from 31% at AM

1.5 to 35%.

A common method used to express economic costs of electricity-generating systems is to calculate a price per delivered kilowatt-hour

(kWh). The solar cell efficiency in combination with the available

irradiation has a major influence on the costs, but generally speaking

the overall system efficiency is important. Using the commercially

available solar cells (as of 2006) and system technology leads to

system efficiencies between 5 and 19%. As of 2005, photovoltaic

electricity generation costs ranged from ~0.60 US$/kWh (0.50 €/kWh)

(central Europe) down to ~0.30 US$/kWh (0.25 €/kWh) in regions of high

solar irradiation. This electricity is generally fed into the

electrical grid on the customer's side of the meter. The cost can be

compared to prevailing retail electric pricing (as of 2005), which

varied from between 0.04 and 0.50 US$/kWh worldwide. (Note: in addition

to solar irradiance profiles, these costs/kwh calculations will vary

depending on assumptions for years of useful life of a system. Most

c-Si panels are warrantied for 25 years and should see 35+ years of

useful life.)

The chart at the right illustrates the various commercial large-area

module energy conversion efficiencies and the best laboratory

efficiencies obtained for various materials and technologies.

Reported timeline of solar cell energy conversion efficiencies (from National Renewable Energy Laboratory (USA)

[edit] Watts peak

Since solar cell output power depends on multiple factors, such as the sun's incidence angle,

for comparison purposes between different cells and panels, the measure

of watts peak (Wp) is used. It is the output power under these

conditions known as STC:[19][20]

- insolation (solar irradiance) 1000 W/m²

- solar reference spectrum AM (airmass) 1.5

- cell temperature 25°C

[edit] Solar cells and energy payback

In the 1990s, when silicon cells were twice as thick, efficiencies

were 30% lower than today and lifetimes were shorter, it may well have

cost more energy to make a cell than it could generate in a lifetime.

In the meantime, the technology has progressed significantly, and the

energy payback time of a modern photovoltaic module is typically from 1

to 4 years [21] depending on the type and where it is used (see net energy gain).

With a typical lifetime of 20 to 30 years, this means that modern solar

cells are net energy producers, i.e they generate much more energy over

their lifetime than the energy expended in producing them.[22][21][23]

[edit] Light-absorbing materials

All solar cells require a light absorbing material contained within the cell structure to absorb photons and generate electrons via the photovoltaic effect.

The materials used in solar cells tend to have the property of

preferentially absorbing the wavelengths of solar light that reach the

earth surface; however, some solar cells are optimized for light

absorption beyond Earth's atmosphere as well. Light absorbing materials

can often be used in multiple physical configurations to take

advantage of different light absorption and charge separation

mechanisms. Many currently available solar cells are configured as bulk

materials that are subsequently cut into wafers and treated in a

"top-down" method of synthesis (silicon being the most prevalent bulk

material). Other materials are configured as thin-films (inorganic layers, organic dyes, and organic polymers) that are deposited on supporting substrates, while a third group are configured as nanocrystals and used as quantum dots

(electron-confined nanoparticles) embedded in a supporting matrix in a

"bottom-up" approach. Silicon remains the only material that is

well-researched in both bulk and thin-film configurations.

There are many new alternatives to Silicon photocells. Proprietary

nano-particle silicon printing processes promises many of the

photovoltaic features that conventional silicon can never achieve. It

can be printed reel to reel on stainless steel or other high

temperature substrates [24].

However, most of the work on the next generation of photovoltaics is

directed at printing onto low cost flexible polymer film and ultimately

on common packaging materials. The main contenders are currently CIGS, CdTe, DSSC and organic photovoltaics[24] .

The following is a current list of light absorbing materials, listed by configuration and substance-name:

[edit] Bulk

These bulk technologies are often referred to as wafer-based

manufacturing. In other words, in each of these approaches,

self-supporting wafers between 180 to 240 micrometers thick are

processed and then soldered together to form a solar cell module. A

general description of silicon wafer processing is provided in Manufacture and Devices.

[edit] Silicon

Basic structure of a silicon based solar cell and its working mechanism.

By far, the most prevalent bulk material for solar cells is crystalline silicon (abbreviated as a group as c-Si),

also known as "solar grade silicon". Bulk silicon is separated into

multiple categories according to crystallinity and crystal size in the

resulting ingot, ribbon, or wafer.

- monocrystalline silicon (c-Si): often made using the Czochralski process.

Single-crystal wafer cells tend to be expensive, and because they are

cut from cylindrical ingots, do not completely cover a square solar

cell module without a substantial waste of refined silicon. Hence most c-Si panels have uncovered gaps at the four corners of the cells. - Poly- or multicrystalline silicon (poly-Si or mc-Si): made

from cast square ingots — large blocks of molten silicon carefully

cooled and solidified. These cells are less expensive to produce than

single crystal cells but are less efficient. - Ribbon silicon: formed by drawing flat thin films from

molten silicon and having a multicrystalline structure. These cells

have lower efficiencies than poly-Si, but save on production costs due

to a great reduction in silicon waste, as this approach does not

require sawing from ingots.

[edit] Thin films

The various thin-film technologies currently being developed reduce the amount (or mass) of light absorbing material required in creating a solar cell.

This can lead to reduced processing costs from that of bulk materials

(in the case of silicon thin films) but also tends to reduce energy conversion efficiency, although many multi-layer thin films have efficiencies above those of bulk silicon wafers.

[edit] CdTe

Cadmium telluride

is an efficient light-absorbing material for thin-film solar cells.

Compared to other thin-film materials, CdTe is easier to deposit and

more suitable for large-scale production. Despite much discussion of

the toxicity of CdTe-based solar cells, this is the only technology

(apart from amorphous silicon) that can be delivered on a large scale[citation needed]. The perception of the toxicity of CdTe is based on the toxicity of elemental cadmium, a heavy metal that is a cumulative poison.

However it has been shown that the release of cadmium to the atmosphere

is lower with CdTe-based solar cells than with silicon photovoltaics

and other thin-film solar cell technologies. [25]

[edit] Copper-Indium Selenide

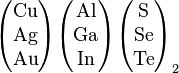

Possible combinations of I III VI elements in the periodic table that have photovoltaic effect |

The materials based on CuInSe2 that are of interest for

photovoltaic applications include several elements from groups I, III

and VI in the periodic table. These semiconductors are especially

attractive for thin film solar cell application because of their high

optical absorption coefficients and versatile optical and electrical

characteristics which can in principle be manipulated and tuned for a

specific need in a given device. CIS is an abbreviation for general

chalcopyrite films of copper indium selenide (CuInSe2), CIGS mentioned below is a variation of CIS. CIS films (no Ga) achieved greater than 14% efficiency.[26]

However, manufacturing costs of CIS solar cells at present are high

when compared with amorphous silicon solar cells but continuing work is

leading to more cost-effective production processes. The first

large-scale production of CIS modules was started in 2006 in Germany by

Wuerth Solar.

When gallium is substituted for some of the indium in CIS, the material is sometimes called CIGS , or copper indium/gallium diselenide, a solid mixture of the semiconductors CuInSe2 and CuGaSe2, often abbreviated by the chemical formula CuInxGa(1-x)Se2. Unlike the conventional silicon based solar cell, which can be modelled as a simple p-n junction (see under semiconductor),

these cells are best described by a more complex heterojunction model.

The best efficiency of a thin-film solar cell as of March 2008 was

19.9% with CIGS absorber layer.[27]

Higher efficiencies (around 30%) can be obtained by using optics to

concentrate the incident light. The use of gallium increases the

optical bandgap of the CIGS layer as compared to pure CIS, thus

increasing the open-circuit voltage. In another point of view, gallium

is added to replace as much indium as possible due to gallium's

relative availability to indium. Approximately 70%[28]

of indium currently produced is used by the flat-screen monitor

industry. Some investors in solar technology worry that production of

CIGS cells will be limited by the availability of indium. Producing 2

GW of CIGS cells (roughly the amount of silicon cells produced in 2006)

would use about 10% of the indium produced in 2004.[29] For comparison, silicon solar cells used up 33% of the world's electronic grade silicon production in 2006. Nanosolar

claims to waste only 5% of the indium it uses. As of 2006, the best

conversion efficiency for flexible CIGS cells on polyimide is 14.1% by

Tiwari et al, at the ETH, Switzerland.

That being said, indium can easily be recycled from decommissioned

PV modules. The recycling program in Germany is an example that

highlights the regenerative industrial paradigm: "From cradle to cradle".

Selenium allows for better uniformity across the layer and so the

number of recombination sites in the film are reduced which benefits

the quantum efficiency and thus the conversion efficiency.[citation needed]

[edit] Gallium arsenide (GaAs) multijunction

High-efficiency multijunction cells were originally developed for special applications such as satellites and space exploration, but at present, their use in terrestrial concentrators might be the lowest cost alternative in terms of $/kWh and $/W.[30] These multijunction cells consist of multiple thin films produced using Metalorganic vapour phase epitaxy. A triple-junction cell, for example, may consist of the semiconductors: GaAs, Ge, and GaInP2.[31] Each type of semiconductor will have a characteristic band gap energy which, loosely speaking, causes it to absorb light most efficiently at a certain color, or more precisely, to absorb electromagnetic radiation

over a portion of the spectrum. The semiconductors are carefully chosen

to absorb nearly all of the solar spectrum, thus generating electricity

from as much of the solar energy as possible.

GaAs based multijunction devices are the most efficient solar cells

to date, reaching a record high of 40.7% efficiency under solar

concentration and laboratory conditions.[32]

This technology is currently being utilized in the Mars rover missions.

Tandem solar cells based on monolithic, series connected, gallium

indium phosphide (GaInP), gallium arsenide GaAs, and germanium Ge pn

junctions, are seeing demand rapidly rise. In just the past 12 months

(12/2006 - 12/2007), the cost of 4N gallium metal has risen from about

$350 per kg to $680 per kg. Additionally, germanium metal prices have

risen substantially to $1000-$1200 per kg this year. Those materials

include gallium (4N, 6N and 7N Ga), arsenic (4N, 6N and 7N) and

germanium, pyrolitic boron nitride (pBN) crucibles for growing

crystals, and boron oxide, these products are critical to the entire

substrate manufacturing industry.

Triple-junction GaAs solar cells were also being used as the power source of the Dutch four-time World Solar Challenge winners Nuna in 2005 and 2007, and also by the Dutch solar cars Solutra (2005) and Twente One (2007).

The dutch Radboud University Nijmegen set the record for thin film solar cell effiency using a single junction GaAs to 25.8% in august 2008 using only 4 µm thick GaAs layer which can be transferred from a wafer base to glas or plastic film. [33]

[edit] Light-absorbing dyes (DSSC)

Typically a ruthenium metalorganic dye (Ru-centered) is used as a

monolayer of light-absorbing material. The dye-sensitized solar cell

depends on a mesoporous layer of nanoparticulate titanium dioxide to greatly amplify the surface area (200-300 m²/g TiO2, as compared to approximately 10 m²/g of flat single crystal). The photogenerated electrons from the light absorbing dye are passed on to the n-type TiO2,

and the holes are passed to an electrolyte on the other side of the

dye. The circuit is completed by a redox couple in the electrolyte,

which can be liquid or solid. This type of cell allows a more flexible

use of materials, and is typically manufactured by screen printing,

with the potential for lower processing costs than those used for bulk

solar cells. However, the dyes in these cells also suffer from

degradation under heat and UV light, and the cell casing is difficult

to seal due to the solvents used in assembly. In spite of the above,

this is a popular emerging technology with some commercial impact

forecast within this decade.

[edit] Organic/polymer solar cells

Organic solar cells and Polymer solar cells are built from thin films (typically 100 nm) of organic semiconductors such as polymers and small-molecule compounds like polyphenylene vinylene, copper phthalocyanine (a blue or green organic pigment) and carbon fullerenes.

Energy conversion efficiencies achieved to date using conductive

polymers are low compared to inorganic materials, with the highest

reported efficiency of 6.5% [34]

for a tandem cell architecture. However, these cells could be

beneficial for some applications where mechanical flexibility and

disposability are important.

These devices differ from inorganic semiconductor solar cells in

that they do not rely on the large built in electric field of a PN

junction to separate the electrons and holes created when photons are

absorbed. The active region of an organic device consists of two

materials, one which acts as an electron donor and the other as an

acceptor. When a photon is converted into an electron hole pair,

typically in the donor material, the charges tend to remain bound in

the form of an exciton,

and are separated when the exciton diffuses to the donor-acceptor

interface. The short exciton diffusion lengths of most polymer systems

tend to limit the efficiency of such devices. Nanostructured

interfaces, sometimes in the form of bulk heterojunctions, can improve

performance [35].

[edit] Silicon Thin Films

Silicon thin-films are mainly deposited by chemical vapor deposition (typically plasma-enhanced (PE-CVD)) from silane gas and hydrogen gas. Depending on the deposition's parameters, this can yield:

- Amorphous silicon (a-Si or a-Si:H)

- protocrystalline silicon or

- Nanocrystalline silicon (nc-Si or nc-Si:H).

These types of silicon present dangling and twisted bonds, which

results in deep defects (energy levels in the bandgap) as well as

deformation of the valence and conduction bands (band tails). The solar

cells made from these materials tend to have lower energy conversion efficiency than bulk silicon, but are also less expensive to produce. The quantum efficiency of thin film solar cells is also lower due to reduced number of collected charge carriers per incident photon.

Amorphous silicon has a higher bandgap (1.7 eV) than crystalline

silicon (c-Si) (1.1 eV), which means it absorbs the visible part of the

solar spectrum more strongly than the infrared portion of the spectrum. As nc-Si has about the same bandgap as c-Si, the two material can be combined in thin layers, creating a layered cell called a tandem cell.

The top cell in a-Si absorbs the visible light and leaves the infrared

part of the spectrum for the bottom cell in nanocrystalline Si.

Recently, solutions to overcome the limitations of thin-film

crystalline silicon have been developed. Light trapping schemes where

the incoming light is obliquely coupled into the silicon and the light

traverses the film several times enhance the absorption of sunlight in

the films. Thermal processing techniques enhance the crystallinity of

the silicon and pacify electronic defects.[citation needed]

A silicon thin film technology is being developed for building

integrated photovoltaics (BIPV) in the form of semi-transparent solar

cells which can be applied as window glazing. These cells function as

window tinting while generating electricity.

[edit] Nanocrystalline solar cells

These structures make use of some of the same thin-film light

absorbing materials but are overlain as an extremely thin absorber on a

supporting matrix of conductive polymer or mesoporous metal oxide

having a very high surface area to increase internal reflections (and

hence increase the probability of light absorption). Using nanocrystals

allows one to design architectures on the length scale of nanometers,

the typical exciton diffusion length. In particular, single-nanocrystal

('channel') devices, an array of single p-n junctions between the

electrodes and separated by a period of about a diffusion length,

represent a new architecture for solar cells and potentially high

efficiency.

[edit] Concentrating photovoltaics (CPV)

Concentrating photovoltaic systems use a large area of lenses or mirrors to focus sunlight on a small area of photovoltaic cells.[36] If these systems use single or dual-axis tracking to improve performance, they may be referred to as Heliostat Concentrator Photovoltaics

(HCPV). The primary attraction of CPV systems is their reduced usage of

semiconducting material which is expensive and currently in short

supply. Additionally, increasing the concentration ratio improves the

performance of general photovoltaic materials.[37]

Despite the advantages of CPV technologies their application has been

limited by the costs of focusing, tracking and cooling equipment. On October 25, 2006, the Australian federal government and the Victorian state government together with photovoltaic technology company Solar Systems announced a project using this technology, Solar power station in Victoria,

planned to come online in 2008 and be completed by 2013. This plant, at

154 MW, would be ten times larger than the largest current photovoltaic

plant in the world.[38]

[edit] Silicon solar cell device manufacture

Solar powered scientific calculator

Because solar cells are semiconductor devices, they share many of

the same processing and manufacturing techniques as other semiconductor

devices such as computer and memory chips.

However, the stringent requirements for cleanliness and quality control

of semiconductor fabrication are a little more relaxed for solar cells.

Most large-scale commercial solar cell factories today make screen

printed poly-crystalline silicon solar cells. Single crystalline wafers

which are used in the semiconductor industry can be made into excellent

high efficiency solar cells, but they are generally considered to be

too expensive for large-scale mass production.

Poly-crystalline silicon wafers are made by wire-sawing block-cast

silicon ingots into very thin (180 to 350 micrometer) slices or wafers.

The wafers are usually lightly p-type doped. To make a solar cell from the wafer, a surface diffusion of n-type dopants is performed on the front side of the wafer. This forms a p-n junction a few hundred nanometers below the surface.

Antireflection coatings, which increase the amount of light coupled

into the solar cell, are typically next applied. Over the past decade,

silicon nitride has gradually replaced titanium dioxide as the

antireflection coating of choice because of its excellent surface

passivation qualities (i.e., it prevents carrier recombination at the

surface of the solar cell). It is typically applied in a layer several

hundred nanometers thick using plasma-enhanced chemical vapor

deposition (PECVD). Some solar cells have textured front surfaces that,

like antireflection coatings, serve to increase the amount of light

coupled into the cell. Such surfaces can usually only be formed on

single-crystal silicon, though in recent years methods of forming them

on multicrystalline silicon have been developed.

The wafer then has a full area metal contact made on the back

surface, and a grid-like metal contact made up of fine "fingers" and

larger "busbars" are screen-printed onto the front surface using a silver

paste. The rear contact is also formed by screen-printing a metal

paste, typically aluminium. Usually this contact covers the entire rear

side of the cell, though in some cell designs it is printed in a grid

pattern. The paste is then fired at several hundred degrees Celsius to

form metal electrodes in ohmic contact

with the silicon. After the metal contacts are made, the solar cells

are interconnected in series (and/or parallel) by flat wires or metal

ribbons, and assembled into modules or "solar panels". Solar panels have a sheet of tempered glass on the front, and a polymer

encapsulation on the back. Tempered glass cannot be used with amorphous

silicon cells because of the high temperatures during the deposition

process.

[edit] Lifespan

A solar cell must be capable of producing electricity for at least twenty years, without a significant decrease in efficiency.

[edit] Low cost solar cells

Dye-sensitized solar cell is considered the low cost solar cell.

This cell is extremely promising because it is made of low-cost

materials and does not need elaborate apparatus to manufacture, so it

can be made in a DIY

way allowing more players to produce it than any other type of solar

cell. In bulk it should be significantly less expensive than older solid-state cell designs. It can be engineered into flexible sheets. Although its conversion efficiency is less than the best thin film cells, its price/performance ratio should be high enough to allow them to compete with fossil fuel electrical generation.

[edit] Current research on materials and devices

- See also: Timeline of solar cells

There are currently many research groups active in the field of photovoltaics in universities

and research institutions around the world. This research can be

divided into three areas: making current technology solar cells cheaper

and/or more efficient to effectively compete with other energy sources;

developing new technologies based on new solar cell architectural

designs; and developing new materials to serve as light absorbers and

charge carriers.

[edit] Silicon processing

One way of reducing the cost is to develop cheaper methods of

obtaining silicon that is sufficiently pure. Silicon is a very common

element, but is normally bound in silica, or silica sand. Processing silica (SiO2)

to produce silicon is a very high energy process - at current

efficiencies, it takes over two years for a conventional solar cell to

generate as much energy as was used to make the silicon it contains.[39]

More energy efficient methods of synthesis are not only beneficial to

the solar industry, but also to industries surrounding silicon

technology as a whole.

The current industrial production of silicon is via the reaction

between carbon (charcoal) and silica at a temperature around 1700 degrees Celsius.

In this process, known as carbothermic reduction, each tonne of silicon

(metallurgical grade, about 98% pure) is produced with the emission of

about 1.5 tonnes of carbon dioxide.

Solid silica can be directly converted (reduced) to pure silicon by

electrolysis in a molten salt bath at a fairly mild temperature (800 to

900 degrees Celsius).[40][41] While this new process is in principle the same as the FFC Cambridge Process

which was first discovered in late 1996, the interesting laboratory

finding is that such electrolytic silicon is in the form of porous

silicon which turns readily into a fine powder, (with a particle size

of a few micrometres), and may therefore offer new opportunities for

development of solar cell technologies.

Another approach is also to reduce the amount of silicon used and

thus cost, is by micromachining wafers into very thin, virtually

transparent layers that could be used as transparent architectural

coverings.[42]

. The technique involves taking a silicon wafer, typically 1 to 2 mm

thick, and making a multitude of parallel, transverse slices across the

wafer, creating a large number of slivers that have a thickness of 50

micrometres and a width equal to the thickness of the original wafer.

These slices are rotated 90 degrees, so that the surfaces corresponding

to the faces of the original wafer become the edges of the slivers. The

result is to convert, for example, a 150 mm diameter, 2 mm-thick wafer

having an exposed silicon surface area of about 175 cm² per side into

about 1000 slivers having dimensions of 100 mm x 2 mm x 0.1 mm,

yielding a total exposed silicon surface area of about 2000 cm² per

side. As a result of this rotation, the electrical doping and contacts

that were on the face of the wafer are located the edges of the sliver,

rather than the front and rear as is the case with conventional wafer

cells. This has the interesting effect of making the cell sensitive

from both the front and rear of the cell (a property known as

bifaciality).[43]

Using this technique, one silicon wafer is enough to build a 140 watt

panel, compared to about 60 wafers needed for conventional modules of

same power output.

[edit] Thin-film processing

Thin-film solar cells use less than 1% of the raw material (silicon

or other light absorbers) compared to wafer based solar cells, leading

to a significant price drop per kWh. There are many research groups

around the world actively researching different thin-film approaches

and/or materials, however it remains to be seen[vague] if these solutions can generate the same space-efficiency as traditional silicon processing.

One particularly promising technology is crystalline silicon thin

films on glass substrates. This technology makes use of the advantages

of crystalline silicon as a solar cell material, with the cost savings

of using a thin-film approach.[citation needed]

Another interesting aspect of thin-film solar cells is the

possibility to deposit the cells on all kind of materials, including

flexible substrates (PET for example), which opens a new dimension for new applications.[citation needed]

One of the R&D Magazine's prestigious R&D 100 Awards — also called the “Oscars of Invention”— for 2008, has gone to National Renewable Energy Laboratory Hybrid CGIS

(or Thin-Film Photovoltaic Manufacturing Process) – hybrid CIGS cells

that are manufactured in layers by using ink-jet and ultrasonic

technology to precisely apply metal-organic inks in separate layers

directly into common building materials such as metal and glass [44].

[edit] Metamorphic Multijunction Solar Cell

The National Renewable Energy Laboratory won another R&D Magazine's R&D 100 Awards

for its Metamorphic Multijunction Solar Cell, an ultra-light and

flexible cell that converts solar energy with record efficiency [44].

The ultra-light, highly efficient solar cell was developed at NREL and is being commercialized by Emcore Corp. [45] of Albuquerque, N.M., in partnership with the Air Force Research Laboratories Space Vehicles Directorate at Kirtland Air Force Base in Albuquerque.

It represents a new class of solar cells with clear advantages in

performance, engineering design, operation and cost. For decades,

conventional cells have featured wafers of semiconducting materials with similar crystalline

structure. Their performance and cost effectiveness is constrained by

growing the cells in an upright configuration. Meanwhile, the cells are

rigid, heavy and thick with a bottom layer made of germanium.

In the new method, the cell is grown upside down. These layers use

high-energy materials with extremely high quality crystals, especially

in the upper layers of the cell where most of the power is produced.

Not all of the layers follow the lattice

pattern of even atomic spacing. Instead, the cell includes a full range

of atomic spacing, which allows for greater absorption and use of

sunlight. The thick, rigid germanium layer

is removed, reducing the cell's cost and 94% of its weight. By turning

the conventional approach to cells on its head, the result is an

ultra-light and flexible cell that also converts solar energy with

record efficiency (40.8 percent under 326 suns concentration).

[edit] Polymer processing

The invention of conductive polymers (for which Alan Heeger, Alan G. MacDiarmid and Hideki Shirakawa were awarded a Nobel prize) may lead to the development of much cheaper cells that are based on inexpensive plastics. However, all organic solar cells made to date suffer from degradation upon exposure to UV light, and hence have lifetimes which are far too short to be viable. The conjugated

double bond systems in the polymers, which carry the charge, are always

susceptible to breaking up when radiated with shorter wavelengths.

Additionally, most conductive polymers, being highly unsaturated and

reactive, are highly sensitive to atmospheric moisture and oxidation,

making commercial applications difficult.

[edit] Nanoparticle processing

Experimental non-silicon solar panels can be made of quantum heterostructures, eg. carbon nanotubes or quantum dots, embedded in conductive polymers

or mesoporous metal oxides. In addition, thin films of many of these

materials on conventional silicon solar cells can increase the optical

coupling efficiency into the silicon cell, thus boosting the overall

efficiency. By varying the size of the quantum dots, the cells can be

tuned to absorb different wavelengths. Although the research is still

in its infancy, quantum dot-modified

photovoltaics may be able to achieve up to 42 percent energy conversion

efficiency due to multiple exciton generation(MEG).[46]

Researchers at the University of California, San Diego have come up with a way of making solar photovoltaic cells more efficient by making them fuzzy with indium phosphide nanowires. It sounds similar to a project announced by a consortium of German universities, working in concert with Harvard University Science department.[47]

[edit] Transparent conductors

Many new solar cells use transparent thin films that are also

conductors of electrical charge. The dominant conductive thin films

used in research now are transparent conductive oxides (abbreviated

"TCO"), and include fluorine-doped tin oxide (SnO2:F, or "FTO"), doped zinc oxide (e.g.: ZnO:Al), and indium tin oxide

(abbreviated "ITO"). These conductive films are also used in the LCD

industry for flat panel displays. The dual function of a TCO allows

light to pass through a substrate window to the active light absorbing

material beneath, and also serves as an ohmic contact to transport

photogenerated charge carriers away from that light absorbing material.

The present TCO materials are effective for research, but perhaps are

not yet optimized for large-scale photovoltaic production. They require

very special deposition conditions at high vacuum, they can sometimes

suffer from poor mechanical strength, and most have poor transmittance

in the infrared portion of the spectrum (e.g.: ITO thin films can also

be used as infrared filters in airplane windows). These factors make

large-scale manufacturing more costly.

A relatively new area has emerged using carbon nanotube networks as a transparent conductor for organic solar cells.

Nanotube networks are flexible and can be deposited on surfaces a

variety of ways. With some treatment, nanotube films can be highly

transparent in the infrared, possibly enabling efficient low bandgap

solar cells. Nanotube networks are p-type conductors, whereas

traditional transparent conductors are exclusively n-type. The availability of a p-type transparent conductor could lead to new cell designs that simplify manufacturing and improve efficiency.

[edit] Silicon wafer based solar cells

Despite the numerous attempts at making better solar cells by using

new and exotic materials, the reality is that the photovoltaics market

is still dominated by silicon wafer-based solar cells (first-generation

solar cells). This means that most solar cell manufacturers are

equipped to produce these type of solar cells. Therefore, a large body

of research is currently being done all over the world to create

silicon wafer-based solar cells that can achieve higher conversion

efficiency without an exorbitant increase in production cost. The aim

of the research is to achieve the lowest cost per watt solar cell

design that is suitable for commercial production.[vague]

IBM has a

semiconductor wafer reclamation process that uses a specialized pattern

removal technique to repurpose scrap semiconductor wafers to a form

used to manufacture silicon-based solar panels. The new process was

recently awarded the “2007 Most Valuable Pollution Prevention Award”

from The National Pollution Prevention Roundtable (NPPR). [48]

[edit] Manufacturers

- Further information: Silicon shortage

Solar cells are manufactured primarily in Japan, China, Germany, Taiwan and the USA [49]

, though numerous other nations have or are acquiring significant solar

cell production capacity. While technologies are constantly evolving

toward higher efficiencies, the most effective cells for low cost

electrical production are not necessarily those with the highest

efficiency, but those with a balance between low-cost production and

efficiency high enough to minimize area-related balance of systems

cost. Those companies with large scale manufacturing technology for

coating inexpensive substrates may, in fact, ultimately be the lowest

cost net electricity producers, even with cell efficiencies that are

lower than those of single-crystal technologies.

No comments:

Post a Comment